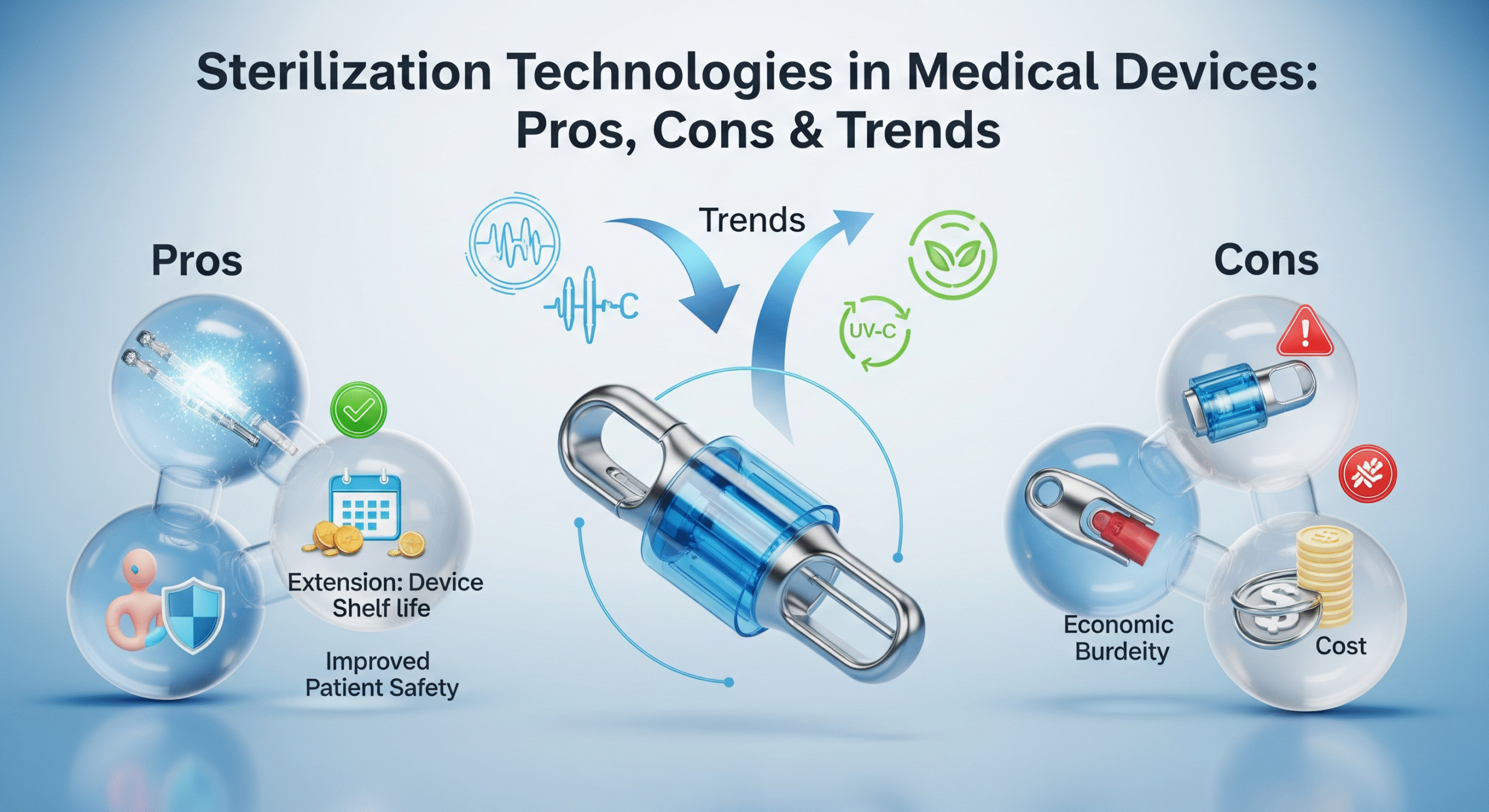

Sterilization Technologies in Medical Devices: Pros, Cons & Trends

Sterilization is one of the most critical steps in the medical device manufacturing process. With rising global demand, stricter regulations, and concerns about patient safety, choosing the right sterilization technique has become a strategic decision for device manufacturers.

This blog explores the most widely used sterilization technologies, their advantages and limitations, and the emerging trends shaping the future of medical device sterilization.

🔬 1. Why Sterilization Matters in Medical Devices

Medical devices—especially those that are invasive, implantable, or come into contact with bodily fluids—must meet strict bioburden and sterility assurance level (SAL) requirements.

Sterilization ensures:

elimination of microorganisms

compliance with FDA, CE, and ISO 11135/11137

extended shelf-life

patient safety and reduced infection risks

⚙️ 2. Major Sterilization Technologies in Medical Devices

2.1 Ethylene Oxide (EtO) Sterilization

How it works:

Uses ethylene oxide gas at low temperature to sterilize heat/moisture-sensitive devices.

✔ Pros:

Ideal for plastics, polymers, electronics, and complex lumens

Penetrates deep into packaging and device cavities

Works at low temperatures → protects delicate materials

High compatibility across device categories

✖ Cons:

Long cycle time (aeration required)

Environmental and worker safety concerns

Increasing regulatory scrutiny (US EPA tightening guidelines)

Best for:

Catheters, wound dressings, syringes, tubing, electronic medical devices.

2.2 Gamma Radiation Sterilization

How it works:

Uses Cobalt-60 gamma rays to destroy microorganisms.

✔ Pros:

Highly reliable & widely used

Faster cycle time vs EtO

Good penetration power

Suitable for bulk processing

✖ Cons:

May degrade certain polymers (e.g., polypropylene)

Requires dedicated, high-cost irradiation facilities

Radioactive material handling challenges

Best for:

Surgical gloves, syringes, IV sets, implants, single-use disposables.

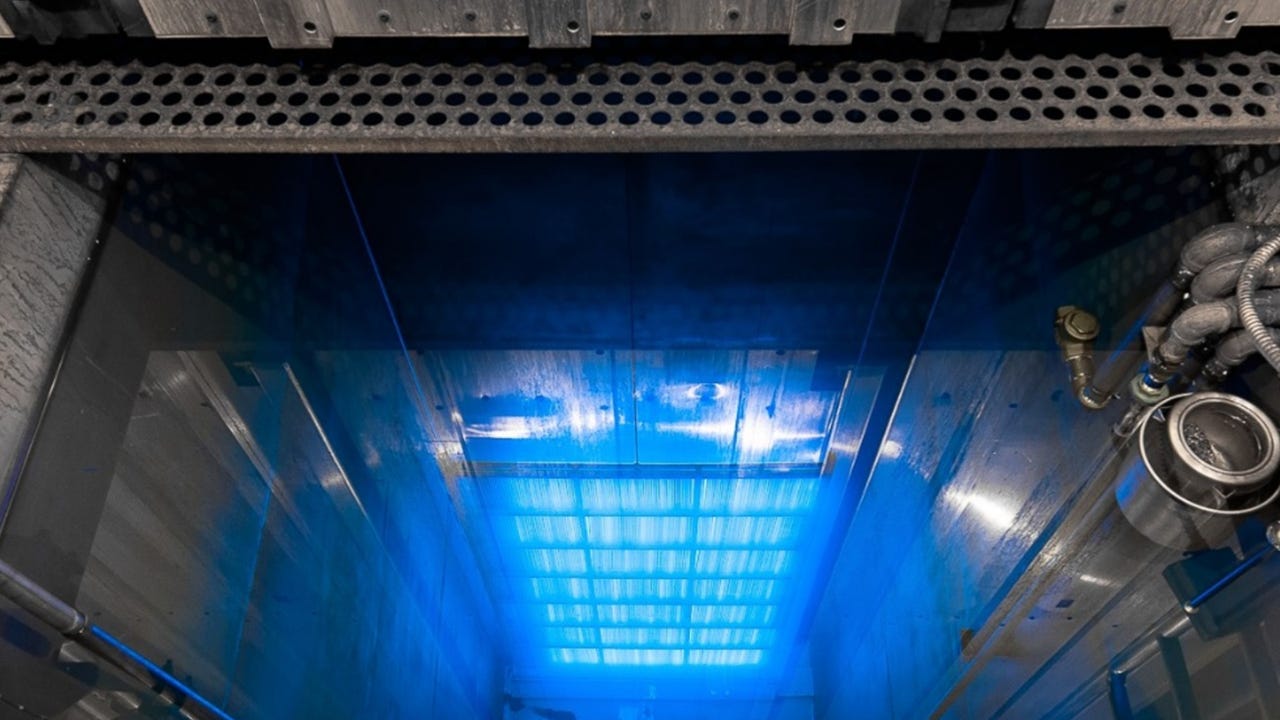

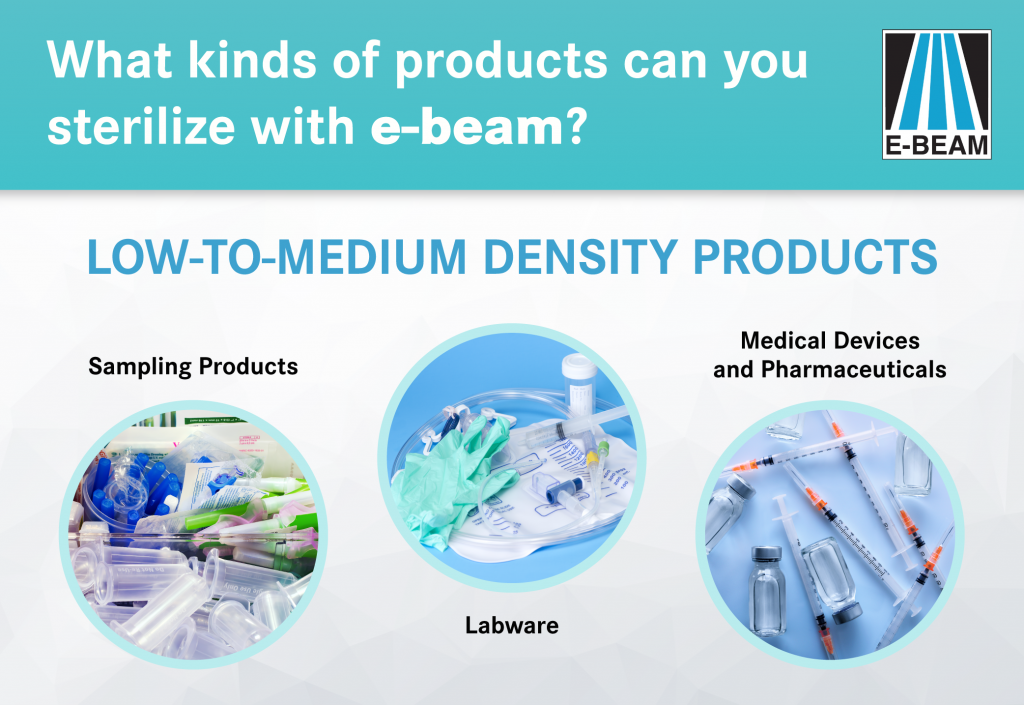

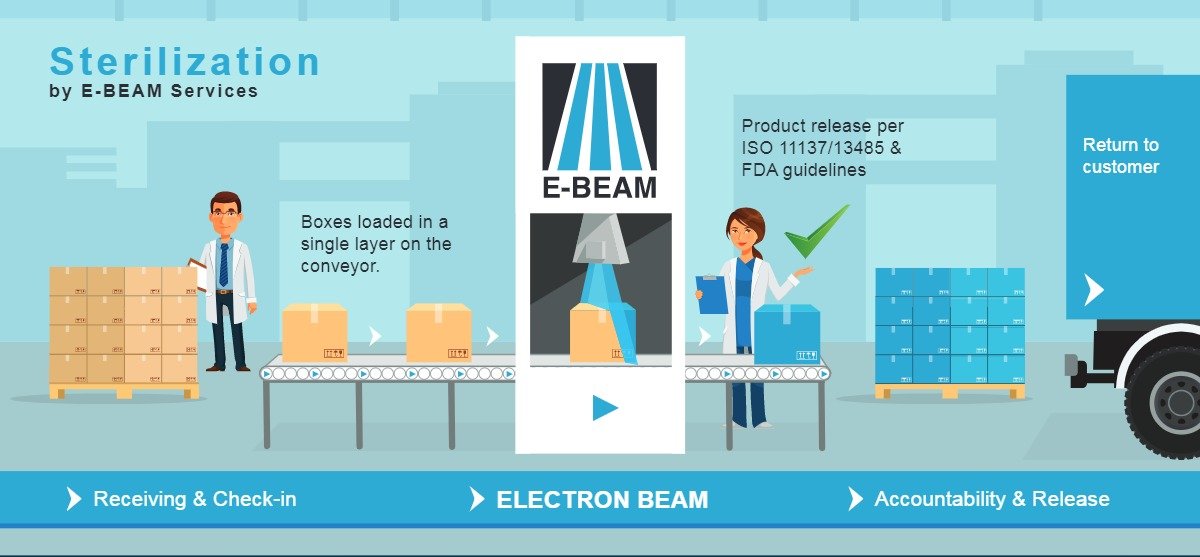

2.3 Electron Beam (E-Beam) Sterilization

How it works:

High-energy electrons sterilize the device surface.

✔ Pros:

Very rapid cycle (< minutes)

No radioactive source used

Suitable for high-volume throughput

Better for thinner materials

✖ Cons:

Limited penetration compared to gamma

Not ideal for densely packaged products

Higher upfront equipment cost

Best for:

Surgical supplies, syringes, drug–device combination products.

2.4 Steam Sterilization (Autoclaving)

How it works:

High-pressure saturated steam (121–134°C).

✔ Pros:

Most cost-effective method

Fast and environmentally friendly

No toxic residues

✖ Cons:

Not suitable for moisture- or heat-sensitive devices

May damage adhesives, electronics, polymers

Best for:

Metal instruments, surgical tools, reusable devices.

2.5 Plasma (Hydrogen Peroxide) Sterilization

How it works:

Uses vaporized hydrogen peroxide + plasma to sterilize at low temperature.

✔ Pros:

Low-temperature, safe, and residue-free

Faster than EtO

Eco-friendly

✖ Cons:

Limited penetration in long lumens

Packaging compatibility issues

Not suitable for cellulose-based materials

Best for:

Endoscopes, cameras, sensitive electronics.

📊 3. Sterilization Technology Comparison Table

| Method | Temperature | Penetration | Material Compatibility | Cycle Time | Cost |

|---|---|---|---|---|---|

| EtO | Low | Excellent | Very High | Long | Medium |

| Gamma | Low | Excellent | High | Medium | High |

| E-Beam | Low | Moderate | Moderate | Very Fast | High |

| Steam | High | Good | Low | Fast | Low |

| Plasma | Low | Moderate | Moderate | Fast | Medium |

🌍 4. Emerging Trends in Medical Device Sterilization

🔹 Trend 1: Shift Away from Ethylene Oxide (Regulatory Pressure)

Global regulatory bodies (EPA, FDA) are tightening EtO emissions standards.

Companies are exploring alternatives like VHP, e-beam, and X-ray.

🔹 Trend 2: Rise of X-Ray Sterilization

X-ray sterilization combines the penetration of gamma with the flexibility of e-beam.

Why it’s growing:

No radioactive material needed

Better supply chain stability

Works for thicker materials

🔹 Trend 3: Sustainability & Green Sterilization

Manufacturers are reducing reliance on ethylene oxide, improving aeration systems, and adopting renewable-energy-powered irradiation.

🔹 Trend 4: Single-Use Devices (SUDs) Driving Volume

The rise of disposables → higher demand for large-scale sterilization facilities.

🔹 Trend 5: Integration of IoT & Automation in Sterilization Facilities

Real-time monitoring, automated cycle validation, and AI-driven quality control are transforming the sterilization workflow.

🔍 5. How to Choose the Right Sterilization Method

Consider these factors:

Material compatibility

Device design (lumens, electronics, coatings)

Regulatory pathway

Throughput requirement

Environmental impact

Cost efficiency

Many companies use multiple sterilization methods depending on product family.

🏁 Conclusion

Sterilization technology is evolving faster than ever, shaped by regulatory pressure, sustainability goals, and technological innovation.

For medical device manufacturers, choosing the right sterilization method is not just a compliance requirement—it’s a strategic decision that impacts product safety, cost, and brand reputation.