Welcome to the exciting world of Metallurgy and Material Science! If you've ever wondered how metals are forged, alloys are created, or materials are manipulated to improve their properties, then you're in the right place. In this article, we'll explore the fascinating field of metallurgy and material science, giving you a glimpse into the science behind the materials that shape our world.

Importance of Metallurgy and Material Science in Various Industries

Metallurgy and material science play a crucial role in various industries, revolutionizing the way we manufacture products, build structures, and develop advanced technologies. From the automotive industry to aerospace, construction, and electronics, the applications of metallurgy and material science are vast and significant.

Metallurgy, the study of metals, involves extracting, purifying, and processing metals to create useful materials. It enables us to understand the behavior of metals under different conditions, allowing for the development of stronger and more durable materials. Material science, on the other hand, focuses on the development and understanding of materials and their properties, not limited to metals. It encompasses polymers, ceramics, composites, and more, broadening the scope of possibilities.

Basics of Metallurgy and Material Science

Metallurgy and material science are interdisciplinary fields that combine elements of chemistry, physics, and engineering. To understand the principles behind these fields, we need to explore the basic concepts that underpin metallurgy and material science.

Metals are elements that possess unique properties, such as high thermal and electrical conductivity, malleability, and ductility. Alloys, on the other hand, are mixtures of two or more elements, including metals, that exhibit superior properties compared to pure metals. Understanding the composition, structure, and properties of metals and alloys is essential in metallurgy and material science.

Different Types of Metals and Alloys

Metals and alloys can be classified into various categories based on their composition and properties. Some common types of metals include ferrous metals (such as iron and steel), non-ferrous metals (such as aluminum, copper, and titanium), and noble metals (such as gold, silver, and platinum). Each type of metal possesses unique characteristics that make it suitable for specific applications.

Alloys, on the other hand, are created by combining different metals or adding non-metal elements to metals. These combinations enhance the properties of the resulting material, making alloys highly versatile and widely used. Some popular alloys include stainless steel, brass, bronze, and aluminum alloys.

Properties and Characteristics of Metals and Alloys

The properties and characteristics of metals and alloys are what make them indispensable in various industries. Metals and alloys exhibit characteristics such as strength, hardness, ductility, and corrosion resistance, which determine their suitability for specific applications.

For example, steel is known for its high strength and durability, making it ideal for construction and manufacturing. Aluminum alloys, on the other hand, are lightweight and have excellent corrosion resistance, making them ideal for aerospace applications. Understanding these properties allows engineers and scientists to select the most appropriate materials for a given application.

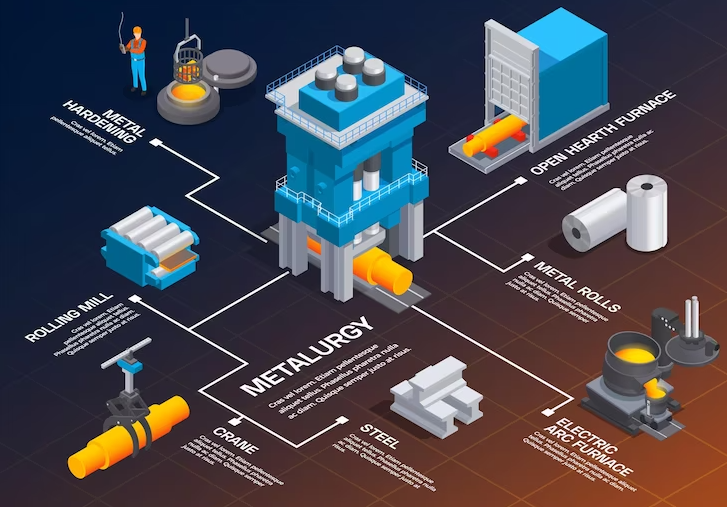

Manufacturing Processes in Metallurgy

Metallurgy involves a range of manufacturing processes aimed at shaping, transforming, and improving the properties of metals and alloys. These processes include casting, forging, rolling, extrusion, and heat treatment, among others.

Casting is a common process used to shape metals by pouring molten metal into a mold and allowing it to solidify. Forging involves shaping metals by applying compressive forces, while rolling and extrusion involve deforming metals by compressive forces.

Heat treatment is another essential process in metallurgy that involves heating and cooling metals to alter their properties. By carefully controlling the heating and cooling rates, engineers can manipulate the microstructure of metals, resulting in desired properties such as increased strength or improved toughness.

Testing and Analysis of Materials

To ensure the quality and reliability of materials, rigorous testing and analysis are conducted in metallurgy and material science. Various techniques, such as spectroscopy, microscopy, and mechanical testing, are used to evaluate the properties and behavior of metals and alloys.

Spectroscopy techniques, such as X-ray diffraction and atomic absorption spectroscopy, allow scientists to analyze the elemental composition and crystal structure of materials. Microscopy techniques, such as scanning electron microscopy and transmission electron microscopy, enable the visualization of the microstructure and defects within materials.

Mechanical testing involves subjecting materials to controlled forces to measure their mechanical properties, such as tensile strength, hardness, and fatigue resistance. These tests help engineers determine the suitability of materials for specific applications and ensure they meet the required standards.

Advancements and Innovations in Metallurgy and Material Science

Metallurgy and material science are constantly evolving fields, driven by advancements in technology and the need for improved materials. Researchers and scientists are continually pushing the boundaries of what is possible, developing new alloys, composites, and materials with enhanced properties.

One area of significant advancement is the development of lightweight materials for transportation applications. Lightweight alloys, such as aluminum and titanium alloys, are being used to reduce the weight of vehicles, improving fuel efficiency and reducing emissions.

Nanomaterials, materials with structures on the nanoscale, are another exciting area of research. Nanomaterials exhibit unique properties due to their small size, such as increased strength, improved electrical conductivity, and enhanced catalytic activity. These materials have the potential to revolutionize industries such as electronics, energy storage, and healthcare.

Career Opportunities in Metallurgy and Material Science

Metallurgy and material science offer a wide range of career opportunities for individuals interested in these fields. From research and development to manufacturing and quality control, there are numerous roles available for professionals with expertise in metallurgy and material science.

Materials engineers, metallurgists, and materials scientists play vital roles in developing new materials, improving manufacturing processes, and ensuring the quality and performance of materials in various industries. These professionals work in industries such as automotive, aerospace, electronics, energy, and healthcare.

Conclusion: The Future of Metallurgy and Material Science

Metallurgy and material science have transformed the way we live, enabling technological advancements and improving the quality of products we use every day. As technology continues to advance, the demand for innovative materials with superior properties will only increase.

The future of metallurgy and material science is filled with exciting possibilities. From developing materials with unprecedented strength and durability to exploring sustainable and environmentally friendly alternatives, researchers and scientists in these fields are shaping the world of tomorrow.

So, whether you’re considering a career in metallurgy and material science or simply fascinated by the science behind the materials that surround us, this field offers endless opportunities for exploration and discovery. Join us in unlocking the secrets of metallurgy and material science and be part of the journey towards a brighter future.