The connection between diet and well-being has never been clearer, with a substantial 74% of Americans acknowledging the impact food and beverages have on their mental and emotional health. As food industry trends evolve, 2024 is set to emphasize nutrition’s critical role in mental and emotional well-being, with growing demand for dietary choices that support mood, sleep, and stress reduction. Additionally, whole foods markets are aligning with these trends, expanding their offerings to include products like functional beverages and plant-based proteins, projected to capture consumer interest.

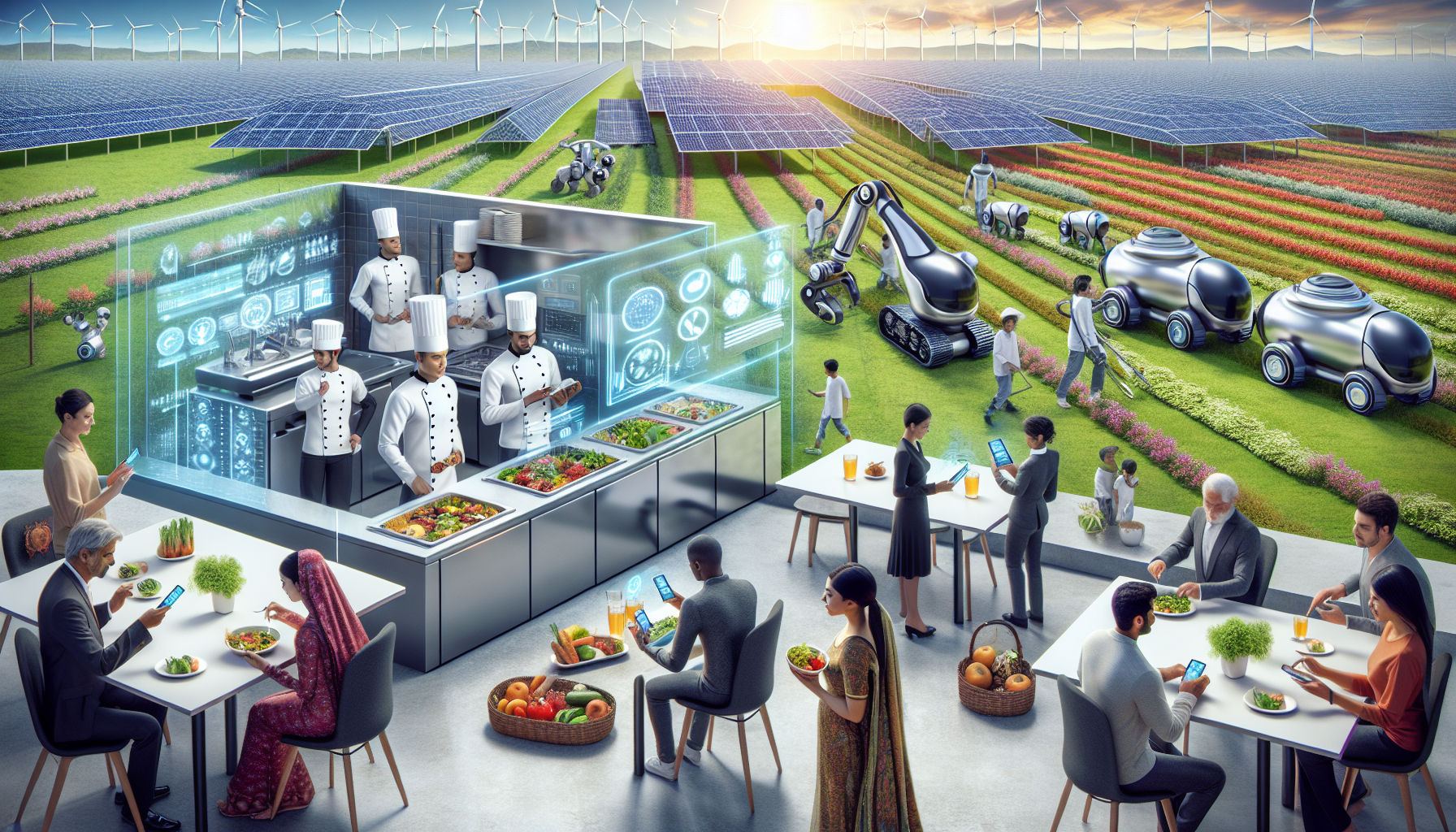

Looking ahead, the food industry is poised to leverage technologies like AI to meet these consumer expectations, enhance transparency in whole foods markets, and embrace sustainable practices. From blockchain’s role in food traceability to the rise of robotics and automation in manufacturing, these advancements promise a transformation in how food reaches the table and the standards consumers hold for their dietary choices.

The Rise of Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) is set to be a game-changer in the food industry by 2024, offering a myriad of benefits from the farm to the consumer’s table:

- Supply Chain and Inventory Management:

- AI-driven algorithms are expected to fine-tune inventory management, predicting demand and adjusting stock levels to minimize waste and ensure supply meets consumer demand.

- Real-time tracking and monitoring of the supply chain will be possible with AI-powered systems, leading to immediate corrective actions for any identified issues.

- Logistics optimization through AI can streamline transportation, reducing costs and improving delivery times for a more efficient supply chain.

- Production and Manufacturing:

- The integration of AI and robotics in food manufacturing is projected to grow significantly, with an estimated market increase of USD 35.20 billion by 2028.

- Robotics will automate repetitive tasks such as food sorting, packaging, and delivery, which not only cuts labor costs but also enhances speed and accuracy.

- AI’s role in quality control will be crucial, ensuring products meet required standards and reducing the risk of human error.

- Agriculture and Farming:

- Precision agriculture powered by machine learning and computer vision will increase crop yields and promote resource conservation.

- Advanced predictive analytics will enhance crop resilience by accurately forecasting weather patterns, leading to better preparedness and yield optimization.

- Customer Experience:

- Personalized recommendations and customer service will be enhanced through AI, with chatbots providing round-the-clock assistance and tailored suggestions based on individual preferences.

- AI-powered analytics will offer insights into consumer behavior, enabling companies to refine their marketing strategies and product offerings for a more personalized touch.

- Innovation in Food Products:

- AI is revolutionizing the way new food products are developed, aligning closely with consumer preferences to reduce the trial-and-error process in product development.

- The discovery of sustainable ingredients is being transformed by AI, which rapidly identifies and develops new components for the market.

These advancements in AI and machine learning are not only expected to improve efficiency and sustainability within the food industry but also to enhance the overall customer experience. As companies like Coca-Cola, Starbucks, Beyond Meat, and Nestlé are already leveraging AI for various purposes including distribution, product personalization, and market analysis, the trend is clear that AI will play a pivotal role in shaping the future of food .

- With the global food automation and robotics market poised for growth, the food sector is on the brink of a significant shift towards AI integration, promising a more sustainable, safe, and customer-centric industry.

Blockchain for Transparency and Traceability

Blockchain technology is revolutionizing the food industry by enhancing the transparency and traceability of supply chains. Here’s how it’s being applied:

- Supply Chain Transparency:

- Utilizes a connected global network to ensure secure data exchange.

- Provides end-to-end traceability of products, guaranteeing their authenticity and compliance with standards.

- Offers a transparent ledger system that documents each step of the value-added process, including origin, quality, and sustainability metrics.

- Challenges and Solutions:

- While the perishable produce industry struggles with data extraction for blockchain, its implementation is crucial for improving supply chain efficiency.

- Companies are actively seeking blockchain solutions despite challenges in collecting and registering necessary information, understanding blockchain functionality, and training staff to manage this data.

- Organizations like GS1 are promoting the use of existing standards to support blockchain integration, emphasizing neutrality in technology adoption.

- Impact on Food Safety and Savings:

- Blockchain can significantly reduce food fraud, with potential savings of $31 billion globally by 2024.

- The technology is expected to cut food loss by 1%-2% through improved traceability solutions [16].

- Companies such as Walmart and Nestlé are implementing blockchain for secure, transparent records, enhancing consumer trust and food safety.

Blockchain’s role in the food industry is still emerging, but its potential to provide a tamperproof, traceable, and transparent system is already being recognized by leading companies. With the FDA supporting the voluntary adoption of traceability tools and retailers driving the requirements for blockchain technology, the food industry is on a clear path toward a more secure and transparent future.

Robotics and Automation in Food Manufacturing

Robotics and automation are increasingly becoming integral components in food manufacturing, addressing efficiency, precision, and labor challenges:

- Efficiency and Precision:

- Robotics in food manufacturing streamline processes, from packaging to cooking, ensuring consistent quality and output.

- The use of innovative machines like the pizza-making machine that produces 100 pizzas per hour exemplifies the potential for enhancing productivity in food manufacturing.

- Labor Challenges:

- With a projected 2.1 million unfilled jobs by 2030 due to a shrinking workforce, robotics fill critical gaps, allowing human workers to focus on more complex tasks.

- Automation has become a solution for many big food chains faced with labor shortages and rising wages, as evidenced by the deployment of Miso Robotics’ “Flippy” in kitchens.

- Operational Optimization:

- The integration of robotics ensures uptime and reduces contamination risks, essential for operational optimization in food processing plants.

- Robotics automation also minimizes the risks of employee injuries, making food manufacturing safer.

The global market for food robotics is witnessing substantial growth, driven by labor scarcity and evolving consumer habits:

- Market Growth:

- The food robotics market is valued at $2.47 billion in 2023 and is projected to grow to $7.8 billion by 2033, marking a significant CAGR of 12%.

- The United States is predicted to generate the highest revenue in this market by 2024, amounting to approximately US$47,710.00k .

- Adoption Drivers:

- Global labor scarcity, particularly in agriculture and food processing sectors, is propelling the adoption of food robotics.

- The shift towards automated food production technologies is creating opportunities for both market leaders and startups, aiming for higher precision and yields.

The future of food manufacturing is embracing robotics for its transformative potential:

- Innovative Applications:

- Robots like BreadBot are taking over the entire baking process, significantly boosting efficiency and reducing human error.

- Robotic delivery systems are gaining popularity for their quick and efficient service, exemplifying the industry’s move towards contactless processes.

- Technological Advancements:

- Companies like Mitsubishi Electric Corporation and Rockwell Automation Inc. are developing new robotics technologies to simplify processing and lifecycle management in the food industry.

- Autonomous tractors and drones are automating traditionally labor-intensive agricultural tasks, as seen with Monarch Tractor’s autonomous farming capabilities.

In summary, robotics and automation are not just transforming food manufacturing but also shaping the future of the entire food industry. With the integration of these technologies, businesses are finding solutions to labor shortages, enhancing efficiency, and ensuring food safety, all while navigating the challenges of a rapidly changing market landscape.

Internet of Things (IoT) and Smart Farming

Precision farming and the Internet of Things (IoT) are revolutionizing agriculture, optimizing operations, and enhancing sustainability. Here’s how these technologies are being integrated into smart farming practices:

- Precision Farming Technologies:

- GPS-guided tractors streamline fieldwork, reducing overlap and saving time.

- Drones, or Unmanned Aerial Vehicles (UAVs), monitor crop health and can apply treatments precisely where needed, with the market for agricultural drones expected to reach $7.19 billion by 2032.

- Sensor-based soil monitors provide real-time data on soil conditions, allowing for more accurate irrigation and fertilization, contributing to the projected $3.1 billion IoT devices market in agriculture by 2028.

- IoT in Crop and Livestock Management:

- Smart irrigation systems use sensors to automate watering, optimizing water usage and reducing waste, as part of the efforts to make farming more sustainable.

- Cattle supervision and greenhouse monitoring are improved through IoT technologies, ensuring healthy livestock and optimal growth conditions for plants.

- Advanced analytics offer insights into yield prediction and field analytics, which is expected to become a $3.95 billion industry by 2030, aiding farmers in making informed decisions.

- Challenges and Opportunities in IoT Adoption:

- While the agriculture IoT market is projected to reach over $18 billion by 2026, the high costs of adoption can be a barrier for small-scale farmers.

- Managing the vast amounts of data generated by IoT devices raises security concerns that need to be addressed.

- There is a growing need for skilled professionals to manage these technologies, especially in developing countries where such expertise may be scarce.

IoT and smart farming are not just about technology; they represent a shift towards data-driven agriculture that prioritizes efficiency and environmental stewardship. As the global population grows, these innovations are key to meeting the increased food production demands sustainably.

Challenges and Opportunities Ahead

Sustainability continues to be a driving force in the food industry, with a shift towards practices that are eco-friendly and promote resource conservation.

Here are some of the challenges and opportunities that lie ahead:

- Sustainable Practices and Consumer Preferences:

- The industry is experiencing a paradigm shift to sustainable and eco-friendly practices from farm to fork, indicating a move towards a more responsible and ethical approach to food production and consumption.

- There is a growing trend in the rise of plant-based and alternative protein sources as consumers seek options that are sustainable and cruelty-free, reducing the environmental impact associated with traditional meat production.

- Circular Economy and Local Sourcing:

- Circular economy practices are crucial for food waste reduction, emphasizing waste minimization, resource efficiency, and the creation of closed-loop systems that are more sustainable.

- Initiatives like farm-to-table and local sourcing are gaining traction, shortening the supply chain, and fostering direct connections between consumers and local producers, which enhances sustainability, freshness, and transparency.

Despite these positive trends, the food industry faces significant challenges that could impact its performance in 2024:

- Industry Challenges:

- The food processing industry must navigate potential recession, inflation, labor shortages, and supply chain disruptions, which could pose threats to its projected good performance.

- Consolidation within the industry may lead to fewer independent and startup brands, which could stifle innovation and diversity in the market.

- Technological Expertise and Equipment Demand:

- As technology continues to play a critical role, there is an increased demand for equipment suppliers who can fill gaps in technological expertise.

- Restaurants and food manufacturers are encouraged to embrace technology, focus on sustainable and ethical practices, and innovate with menus to overcome these challenges and enhance the dining experience.

Sustainable packaging and efficiency are also areas where food and beverage manufacturers need to find a balance to maintain profitability:

- Sustainability and Efficiency:

- Sustainable packaging is becoming increasingly important, with a significant impact on the industry’s approach to environmental responsibility.

- Manufacturers are advised to improve cost management, energy management, and gather better data to ease the burden of regulatory compliance and reduce associated costs.

Conclusion

As the food industry prepares to embrace 2024, the forerunners are realigning their strategies to harness the power of AI, blockchain, and automation to meet evolving consumer demands and tackle sustainability challenges. The convergence of these technologies not only promises enhanced efficiency across supply chains but also aligns with a global movement towards responsible consumption, eco-friendly practices, and innovative food solutions. Acknowledging the significant strides in precision agriculture and smart farming, the industry sets a benchmark in promoting environmental stewardship while navigating operational challenges.

The transformative journey of the food sector is indicative of a future where transparency, consumer trust, and sustainability are not just aspirations but functional norms. As companies and manufacturers continue to push the boundaries of what’s possible, they create a robust blueprint for a more secure and customer-centric industry. In the spirit of advancement, we are invited to witness and contribute to this evolution—for insights, and collaborations, or to stay informed on these exciting developments, join the conversation and explore the future possibilities in the food industry.